Pennsylvania Manufacturing Advisory Council Releases Playbook for Competitiveness

DMI Companies, Inc.’s President and CEO Ray Yeager has worked closely with the Pennsylvania Manufacturing Advisory Council and other manufacturers for the past 18 months to develop a complete Manufacturing Competitiveness Playbook that is now available to the public.

DMI is a World Class Manufacturing enterprise because of its employees and strategic plan for success. All Pennsylvania manufacturers can reach this level of success if they utilize the Playbook blueprint.

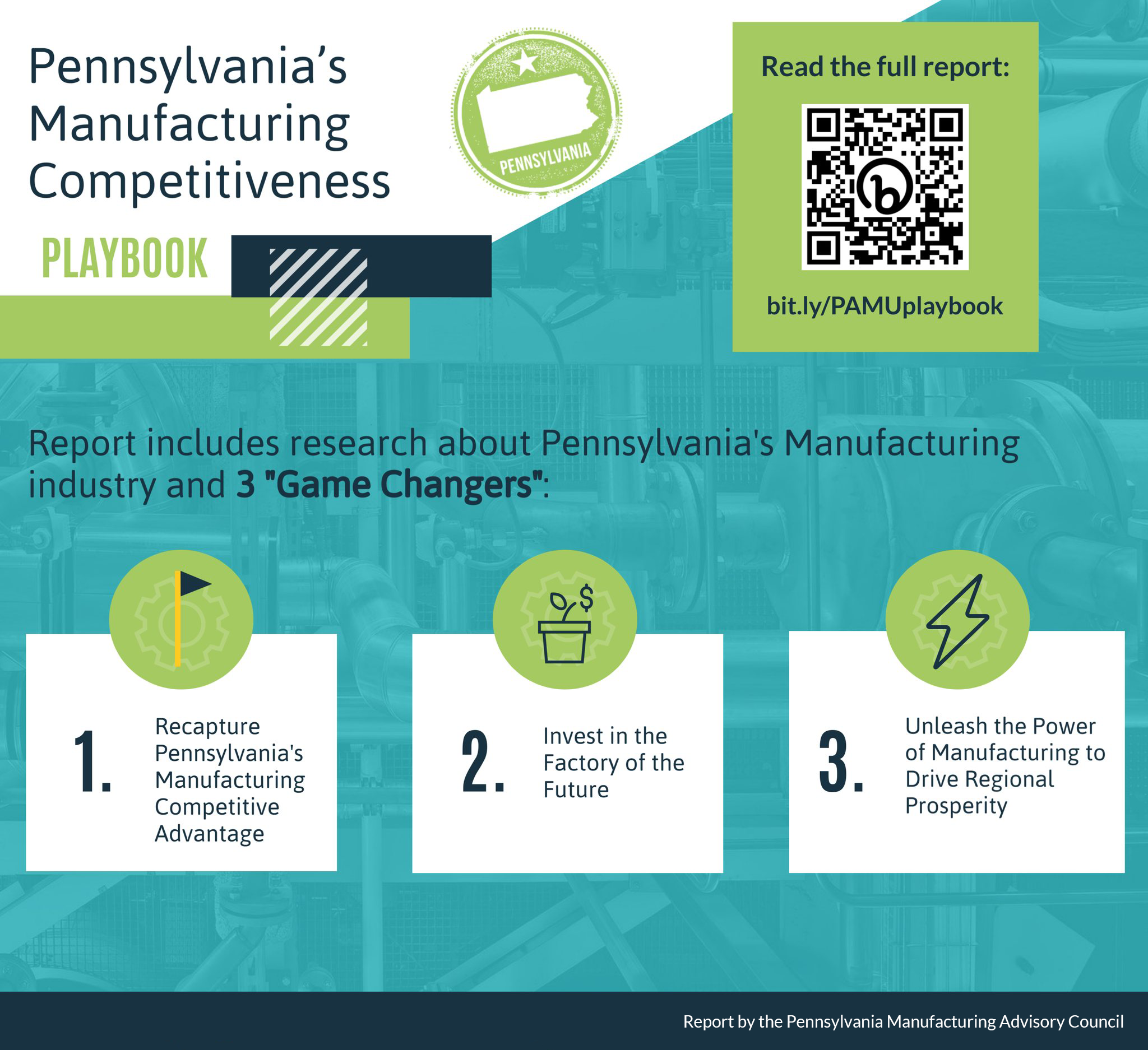

The Playbook recommends three game changers for improving Pennsylvania manufacturing’s competitive position:

• Recapture Pennsylvania’s manufacturing competitive advantage by aggressively pursuing manufacturing growth sectors to drive prosperity.

• Invest in the factory of the future to boost the performance of small and medium-sized companies, improve the quality of manufacturing jobs, and provide better career options for more of Pennsylvania’s citizens.

• Unleash the power of advanced manufacturing to drive regional prosperity through policies and services that are more responsive to the needs of manufacturers.

The manufacturing sector is fundamental to Pennsylvania’s economic success, can compete more effectively, and offers a growing number of well-paying jobs, but the sector needs the commonwealth’s help. That’s the findings from a new report released by the Pennsylvania Manufacturing Advisory Council, a nonpartisan partnership of manufacturers and public support organizations. Pennsylvania’s Manufacturing Competitiveness Playbook identifies three game changers for Pennsylvanian manufacturing and offers ten actionable strategies to help make Pennsylvania’s manufacturing economy more robust and resilient.

“It’s vital that we do more for manufacturing because it represents one of Pennsylvania’s largest sectors, pays better than most others, and offers good benefits,” COO of the Berks County Workforce Development Board and Council Co-Chair Dan Fogarty said. “The Playbook is a great first step toward coming together around how we can be there for the sector and for communities across the Commonwealth that both support and benefit from our great industrial employers,” he added.

Manufacturing contributes $113 billion to Pennsylvania’s GDP and employs an estimated 563,000 Pennsylvanians. Pennsylvania’s Manufacturing Competitiveness Playbook includes recommendations developed by a group of 25 manufacturing and public leaders with the help of recommendations and insights offered by more than 500 manufacturers from across the Commonwealth.

The Playbook builds on Pennsylvania’s historic strengths in manufacturing and captures a vision for Pennsylvania’s future as a global leader in advanced manufacturing.

DMI urges Pennsylvania manufacturers to take the time to read the Playbook and share it with their colleagues, friends, and business associates.

CLICK HERE to download the full Playbook from the Manufacturing Advisory Council’s website.