Generic Hangers We’ll Hang Our Reputation On

Small components in ductwork, like generic ductwork hangers, are often overlooked. However, they provide a secure and reliable way to support and suspend ductwork from ceilings or structural supports. These hangers help prevent sagging and vibration, ensuring that the ductwork remains properly aligned and efficient. They come in various sizes and styles to accommodate different duct diameters and installation requirements.

Ductmate offers a variety of generic hangers that are cost-efficient, easy to use, and require no prep work, making ductwork installation easier, faster, and safer. Learn more about the different hangers that Ductmate has to offer below.

What Generic Hangers Does Ductmate Offer?

Pre-Punched Trapeze Duct Hanger

The Pre-Punched Trapeze Duct Hanger simplifies ductwork installation. This lightweight, 18-gauge galvanized steel hanger is easy to cut and install, saving you time and effort by replacing hard-to-cut and punch angle iron. It is also low in theft because it is exclusively sold to the HVAC industry.

Engineered for stability and noise reduction, our Isolation Hanger Type SI is a quiet, strong, and simple solution for reducing the transmission of vibration and noise from suspended mechanical equipment such as fans, pumps, air handling units, piping, and ductwork. The sturdy steel bracket designed for a 3/8” threaded rod, coupled with a high-density rubber isolation pad, supports up to 1,100 pounds while effectively preventing vibrations from being transmitted. Installation is a breeze due to its standard wrench-friendly design.

Install your round ductwork quickly and effortlessly with our Round Duct Hanger. This prefabricated hanger features a ¼” x 20 carriage bolt with a zinc-plated wing nut and lock washer for secure, tool-free installation. Available in a range of sizes from 3” to 10” in 1” increments and 12” to 34” in 2” increments to perfectly fit your ductwork. Constructed from durable 20-gauge galvanized metal for long-lasting performance.

Our versatile Round Duct Strap Bracket supports ductwork up to a generous 50” diameter. Designed to accommodate 1” wide strapping in gauges 18-22, it offers flexible installation options. Easily attach your preferred hanging system with compatibility for Cable Shark Hanger Adapters, 3/8” and 5/16” rods, or eyebolts. This bracket is a crucial component for secure and efficient ductwork suspension when used in conjunction with strapping and your chosen hanging method.

Our versatile Hanger Strapping makes it easy to tackle hanging ductwork. Available in convenient boxes, bundles, or coils and in galvanized and stainless-steel options, this essential component is perfect for even the most challenging installations.

Quickly and easily secure your flexible or lightweight ductwork with our Vinyl Duct Strapping. This strong, all-purpose fabric is perfect for small-scale installations, and its durable construction ensures reliable support for hanging your ductwork.

Defend your HVAC system against the harshest weather conditions with the Hurricane Air Brace. Engineered and certified to withstand extreme lateral and uplift wind pressures, it meets stringent Florida Building Codes.

Maximize your system’s efficiency with improved airflow and reduced blockage while safeguarding your units from storm surge damage. Our heavy-duty, laser-cut design in galvanized or 304 stainless steel ensures long-lasting performance. Plus, with no need for ground leveling or final grading, installation is quick and hassle-free.

Factors to Consider When Choosing Duct Hangers:

- Duct Size & Weight: The hanger must be able to support the weight of the duct.

- Installation Location: The type of hanger will depend on where the duct is located (ceiling, wall, etc.)

- Environmental Conditions: The hanger material should be resistant to corrosion and other environmental factors.

- Code Requirements: Local building codes may have specific requirements for duct hanger installation.

While the term “generic duct hangers” is often used, it’s important to select hangers that are specifically designed for HVAC applications to ensure proper support and safety.

Where Can I Buy Ductmate Hangers?

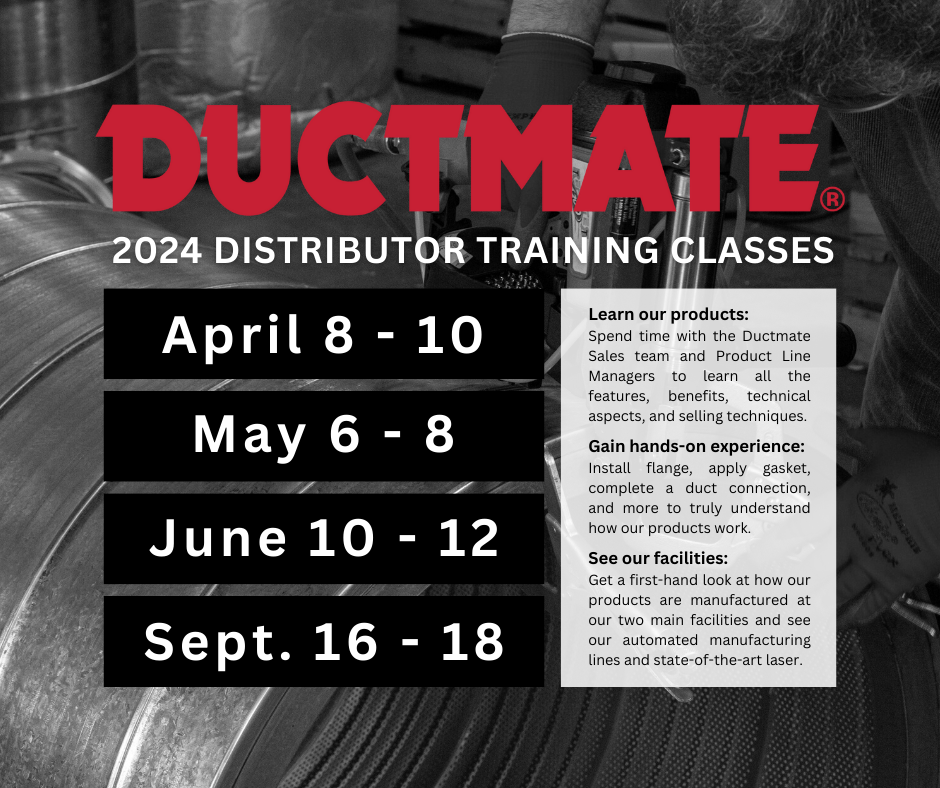

Ready to buy Ductmate hangers? Ductmate products are available at over 350 locations across the US as part of a selective distribution network. Use the Ductmate distributor locator map to find a distributor near you.

Outside the US? Check out our international distributor list. For detailed information on product availability, lead times, or other international sales requests, please email [email protected].