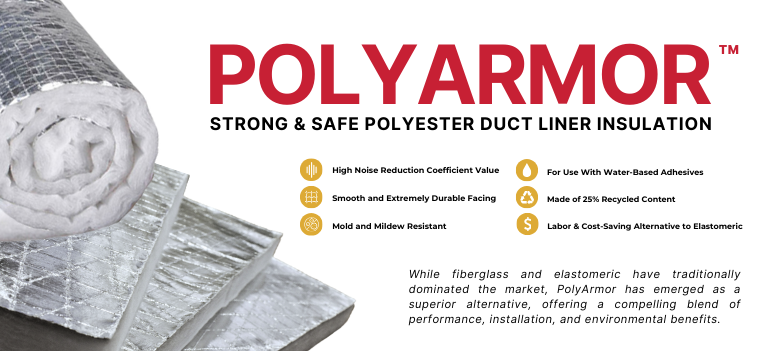

PolyArmor vs. Traditional Fiberglass & Elastomeric Duct Liner Insulations

While fiberglass and elastomeric duct liner insulation have traditionally dominated the market, Ductmate’s PolyArmor polyester insulation has emerged as a superior alternative, offering a compelling blend of performance, installation, and environmental benefits.

Fiberglass: The Traditional Choice with Limitations

Fiberglass insulation is known for its affordability and thermal resistance. However, it presents several drawbacks:

- Fiber Shedding: Fiberglass easily breaks down and releases microscopic fibers into the airstream, posing potential health risks and requiring careful handling and installation. In time, this can lead to costly repairs and replacement of the insulation.

- Moisture Absorption: While fiberglass itself does not provide food for mold, when it does collect moisture, dust, dirt, and other organic debris trapped inside can act as a breeding ground for mold.

- Installation Challenges & Environmental Concerns: Installing fiberglass can be challenging, requiring specialized tools and protective gear. During installation or if the insulation is disturbed, some individuals may experience temporary irritation of the skin, eyes, nose, and throat from both the fiberglass fibers and the formaldehyde released.

- Reduced Effectiveness: If fiberglass insulation is compressed, its thickness will go down, leading to a reduced overall R-value/thermal resistance.

Elastomeric: Flexibility and Moisture Resistance at a Cost

Elastomeric insulation, often favored for its flexibility and closed-cell structure, offers excellent moisture resistance and condensation control. However, it also comes with its own set of drawbacks and considerations:

- Higher Cost: Not only is elastomeric material more expensive compared to other insulation types, but it also can be up to four times more expensive to install.

- Installation Complexity: Proper elastomeric installation requires specialized adhesives and techniques that significantly increase installation and labor costs.

- Can Break Down: Over time, elastomeric, especially when exposed to exterior conditions, can break down due to factors like UV light and mechanical damage. This can lead to costly repairs and replacement of the insulation.

PolyArmor: A Strong, Safe, and Superior Alternative

Ductmate’s PolyArmor polyester insulation is engineered to address the shortcomings of traditional insulation materials, offering a superior alternative with several compelling advantages:

- Fiber-Free and Safe: PolyArmor eliminates fiber shedding and does not break down in the airstream, creating a cleaner and healthier indoor environment. Its polyester material is soft and hypoallergenic, eliminating irritation during handling that you would typically experience with fiberglass insulation.

- Superior Moisture Resistance: PolyArmor’s polyester construction provides exceptional resistance to moisture and condensation, minimizing the risk of mold growth.

- Easy Installation: Designed for ease of installation, PolyArmor reduces labor costs and installation time, with its flexible nature allowing it to conform to any duct shape.

- Enhanced Thermal Performance: PolyArmor provides industry-leading R-values/thermal resistance, contributing to increased energy efficiency and reduced system load.

- Durability and Longevity: PolyArmor is engineered from strong and safe polyester that is webbed into a thermal blanket, which is then bonded with an extremely durable FSK-facing that reduces damage during fabrication, operation, and cleaning.

- Environmental Benefits: Made with environmental sustainability in mind, PolyArmor is manufactured from 25% recycled content.

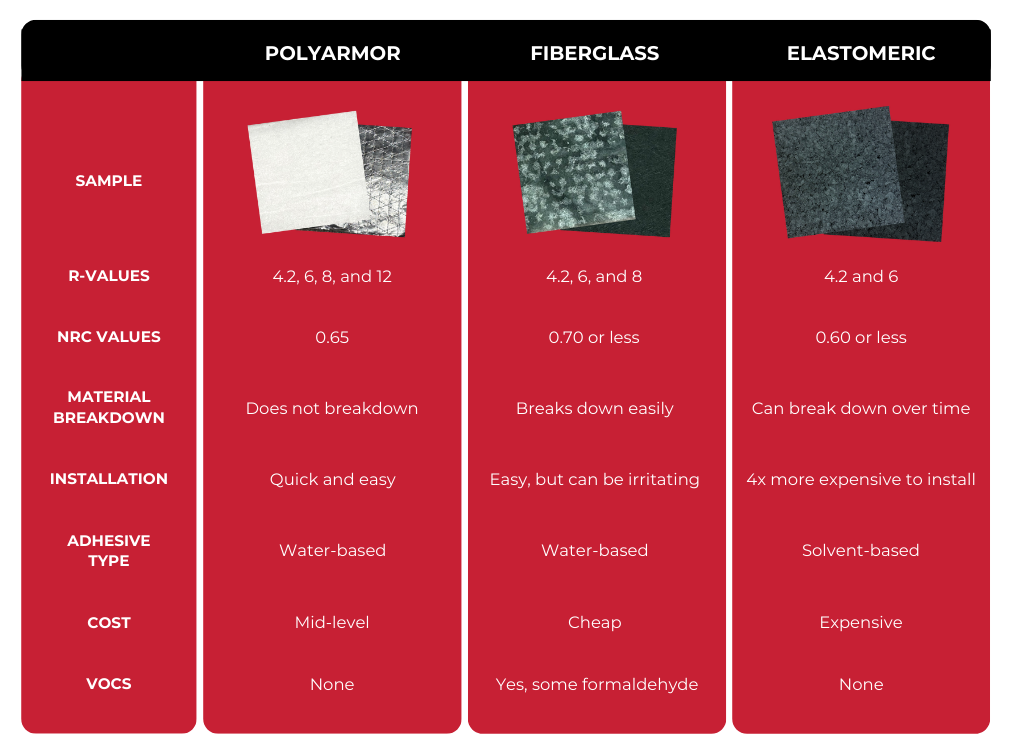

Quick Comparison Chart

Where Can I Buy PolyArmor?

Ready to buy PolyArmor? Ductmate products are available at over 350 locations across the US as part of a selective distribution network. Use the Ductmate distributor locator map to find a distributor near you.

Outside the US? Check out our international distributor list. For detailed information on product availability, lead times, or other international sales requests, please email [email protected].